Disinfection with UV-C

A safe, cost-effective and environmentally friendly method

How does the UV-C Disinfection work on water, air and surfaces?

Besides our medium pressure UV lamps, used in the most

various curing and polymerisation processes, PGUVLAMPS

offers a wide range of systems and spare parts for UV-C

disinfection of water, air and surfaces.

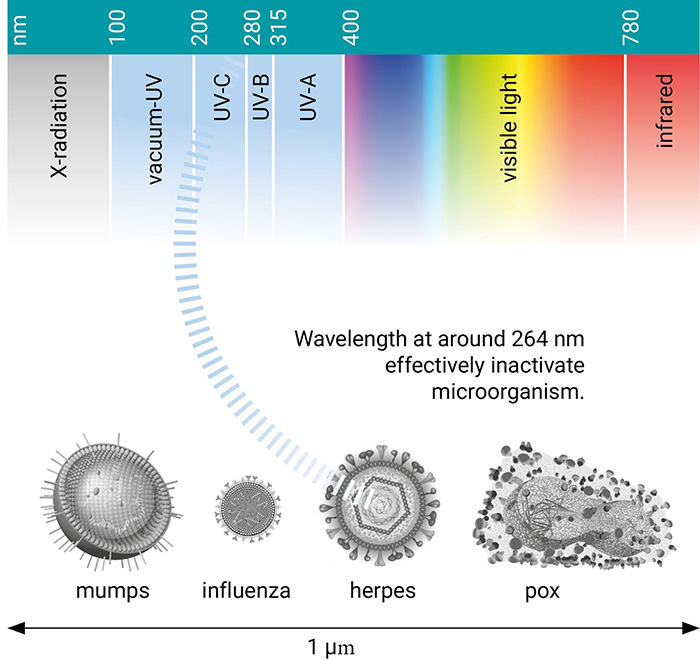

Disinfection with UV-C light is becoming the popular alternative to chemical disinfection: a safe, eco-friendly and highly-effective method where microorganisms such as bacteria, molds, yeasts and protozoa are destroyed or inactivated exclusively through a UV induced reaction using monochromatic radiation within the wave length range of 200-300 nm. This means that the disinfection process occurs without addition of chemicals and without influencing organoleptic properties. Furthermore, microorganisms don’t develop resistance against UV-radiation.

Through high quality standards, first class components and advanced production methods we ensure reliable, high-performing and long lasting products. Our customer's needs and requirements are always priority for us.

UV-C Disinfection is:

- Fast: Deactivation of microorganisms within seconds

- Eco-friendly: without addition of chemicals = no chemical residues, no modification of water pH value = not affecting smell or taste

- Highly versatile for treatment of liquids, air and surfaces

- Effective: enhanced durability, better appearance and higher quality of treated products

- Safe and reliable: high operational safety, it helps to prevent resistance development of microorganisms, impossible to overdose on UV

- Easy handling, low maintenance requirements, different options for assembling

- Safe and low-risk, if precautionary measures are observed

- Cost-effective

The operational costs of UV-C systems are basically composed of:

- Energy costs

- Costs for replacements

- Maintenance costs

Since the investment and operational costs of these UV-C systems are normally very low, the economy of UV-C disinfection is high: the components of UV-C systems, starting from the UV lamps, are very long lasting, the operation requires low-maintenance and the energy consumption of the UV-C systems is relatively low.

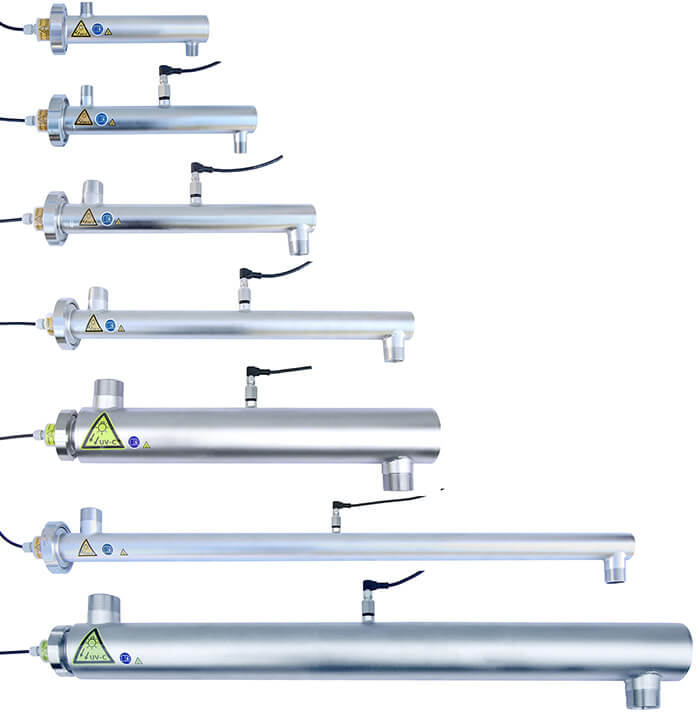

UV-C Disinfection systems for - water, air and surface

Solutions for water treatment

UV systems provide a chemical-free solution for a range of marine water treatments such as drinking water, waste water, swimming pool treatment, aqua culture and ballast water. A problem with storing fresh water is the increase in multi-resistant germs despite the use of chlorine and different chemical additives. UV disinfection helps tackle this as disinfects the water more effectively without the use of chemicals creating higher quality water.

For Use:

- Industry (process water for food and drinks, cooling water circuits, ultra pure water)

- Agriculture, animal husbandry

- Private households and public water treatment (Supply and disposal, potable water and gray water)

- Humidifier

- Pools, pharmaceutics

- Water for snow cannons, greenhouse, aquarium and fish ponds

- Ballast water for vessels

Solutions for air treatment

UV air disinfection improves the quality of your produce

by assuring a bacteria free environment. It can do this

without it damaging or modifying the physical characteristics

of your product.

For dry room and humid room With and without splinter

protection Open and closed systems Suitable for direct

and indirect radiation

For:

- Supply air, recirculating air, exhaust air, sterilization

- Low-germ air through UV radiance

- Medical technology, laboratories, ripening rooms

- Disinfection of humidifier and air conditioner

- Greenhouse

Solutions for surface treatment

UV-Modules and equipment for:

- Disinfection of assembly lines, transport container and products airlocks

- Surface disinfection, benches

- Disinfection of packaging material and packaging’s before the filling (food and drinks)

- Installation in air conditioning ducts

- Laboratory hygienic and medical engineering

- Ripening rooms

UV-C Emitter

Low pressure vapour lamp = monochromatically spectrum in wavelength range 200-300 nm.

UV-C emitters are

- long lasting (replacement of emitters approximately once a year)

- easy to install, to manage and to maintain

- environmental friendly

General differentiation of UV-C lamps

Ozone free, ozone generating and intense ozone

generating low pressure vapour (mercury doped)

Ozone free, ozone generating and intense ozone

generating amalgam lamps

Standard quartz or synthetic quartz

With various mechanical features: length, diameter,

socket (one-sided/two-sided) or geometry

PGUVLamps - Replacement Components

In addition to the difference of intermediate pressure and low pressure lamps PGUVLamps has as a complete system supplier also all accessories like sheath, sensors etc. in their assortment. Technical requirements require constant service and replacements to keep their operational readiness up. A fast and reliable availability as well as the highest quality of the components are indispensable.

Along with the above mentioned emitters we also deliver system accessories and components which are required to operate the UV equipment.

- Immersion tubes / module

- electronic power supplies / ballasts

- sensor systems and electronics

40 year of experience and development in production of UV lamps!